Our Group Companies

-

Call Us

-

Write Us

PRODUCTS

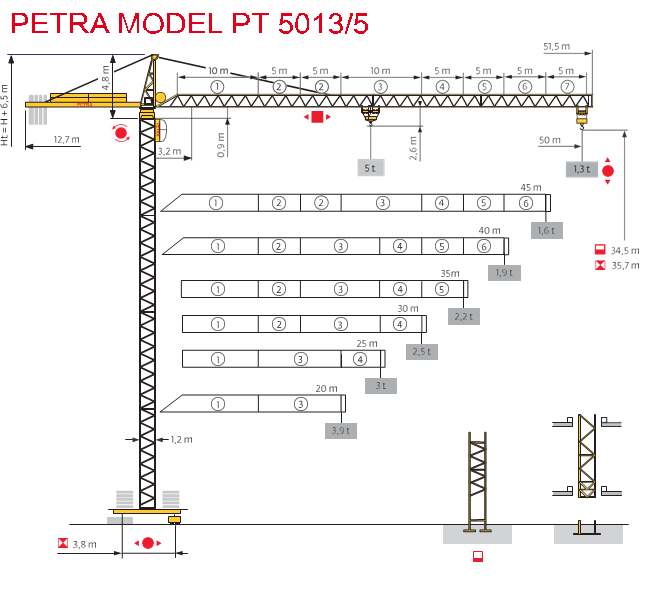

Kule Vinç PETRA5013-5

İncele »

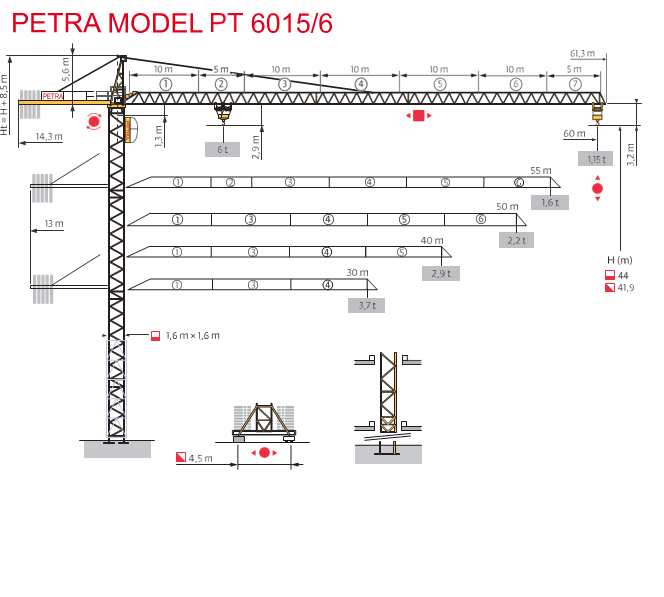

KULE VİNÇ 6015-6

İncele »

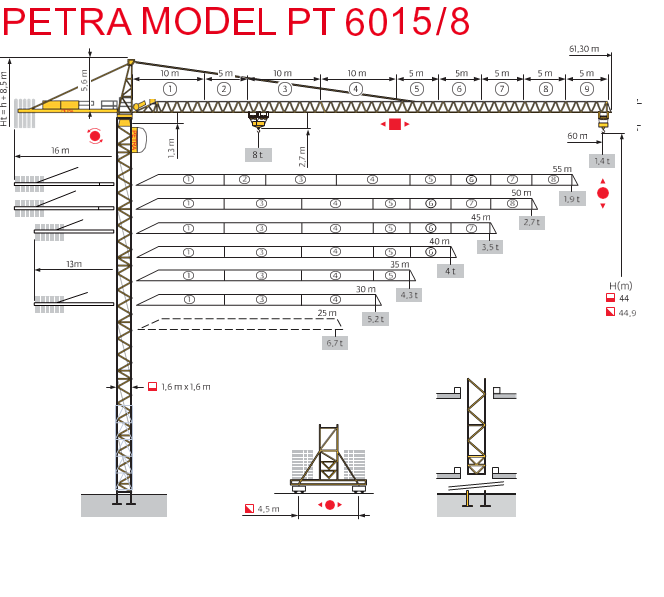

KULE VİNÇ 6015-8

İncele »

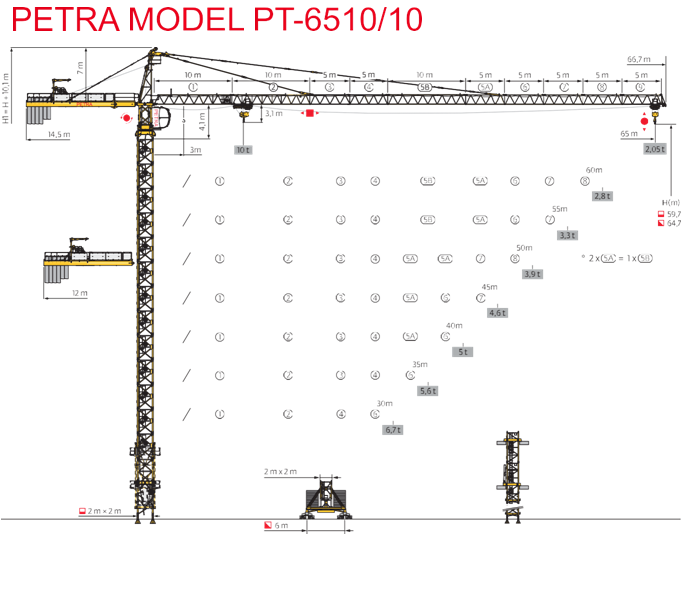

KULE VİNÇ 6510-10

İncele »

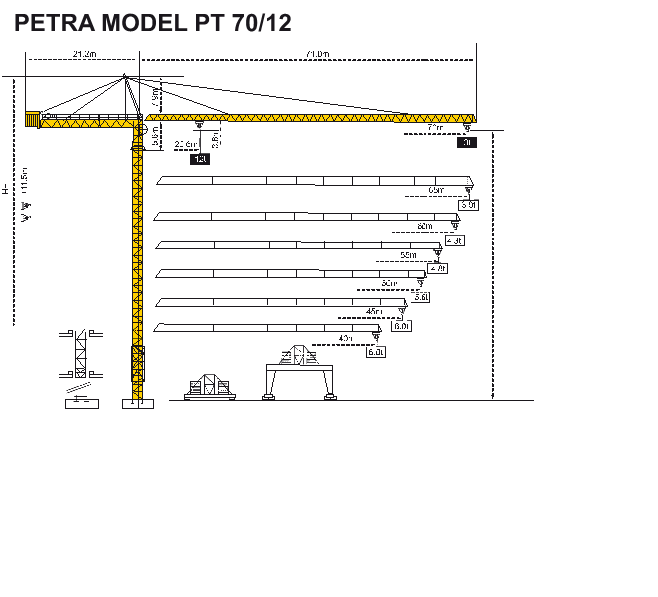

KULE VİNÇ PT-7012

İncele »

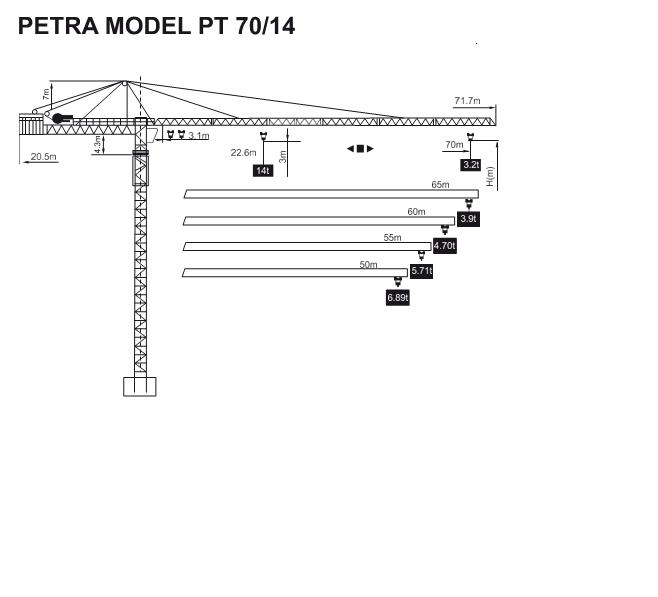

KULE VİNÇ PT-7014

İncele »

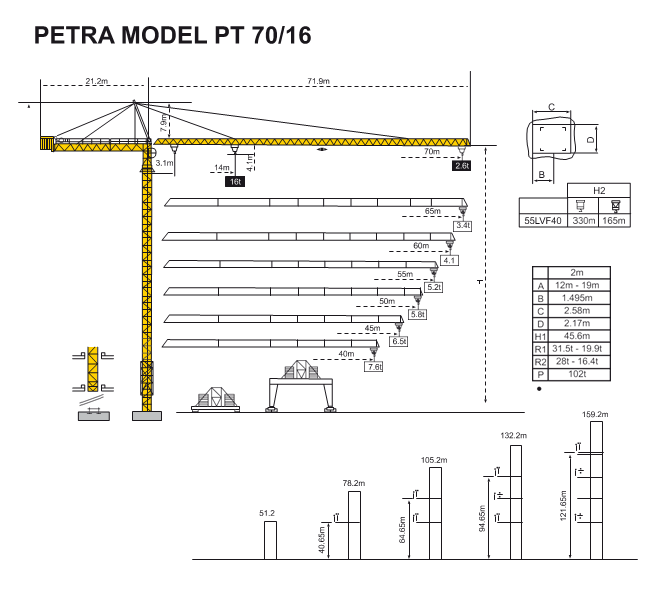

KULE VİNÇ PT-7016

İncele »

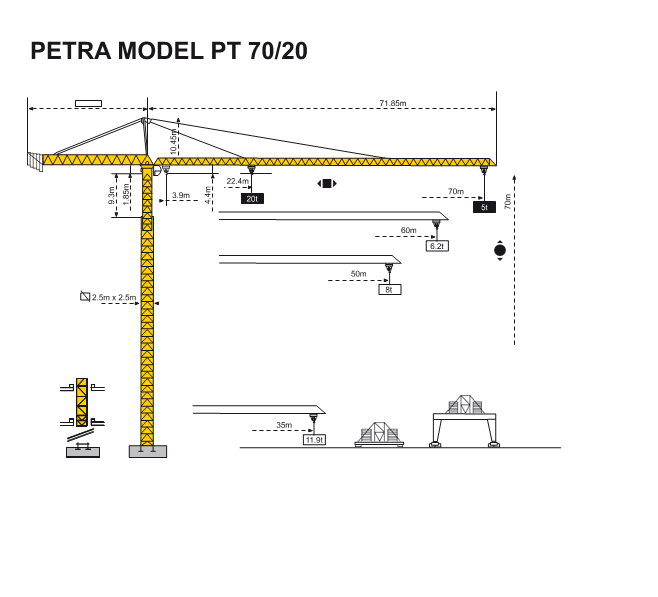

KULE VİNÇ PT-7020

İncele »

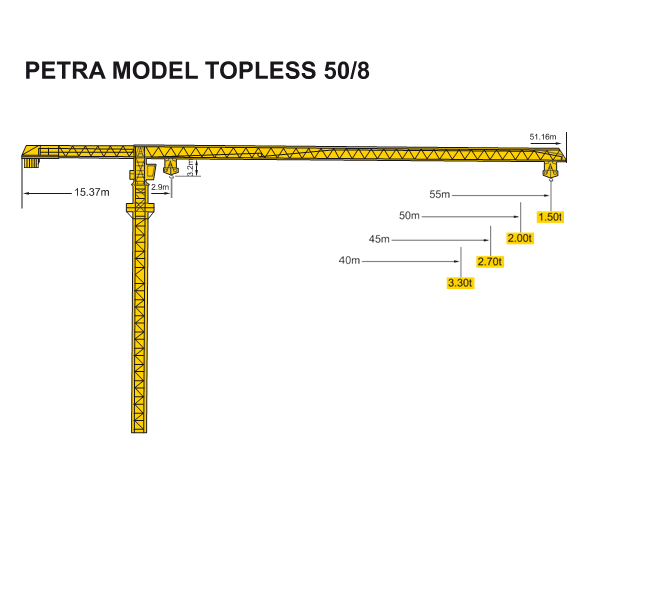

KULE VİNÇ TOPLESS 50-8

İncele »

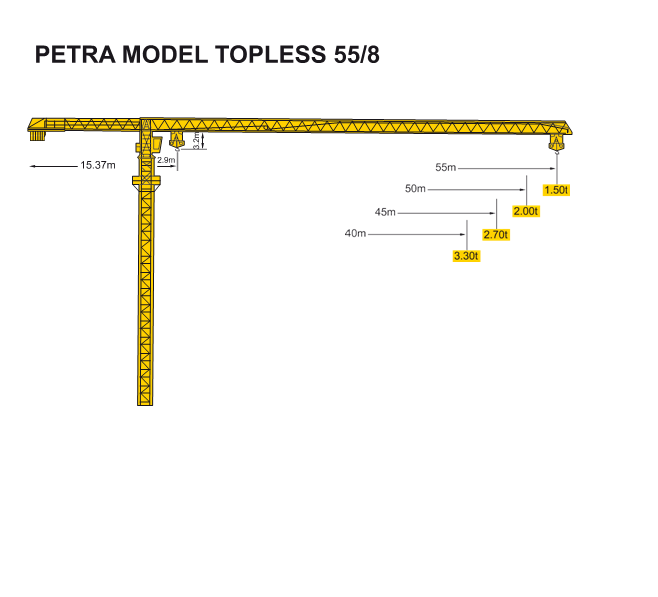

KULE VİNÇ TOPLESS 55-8

İncele »

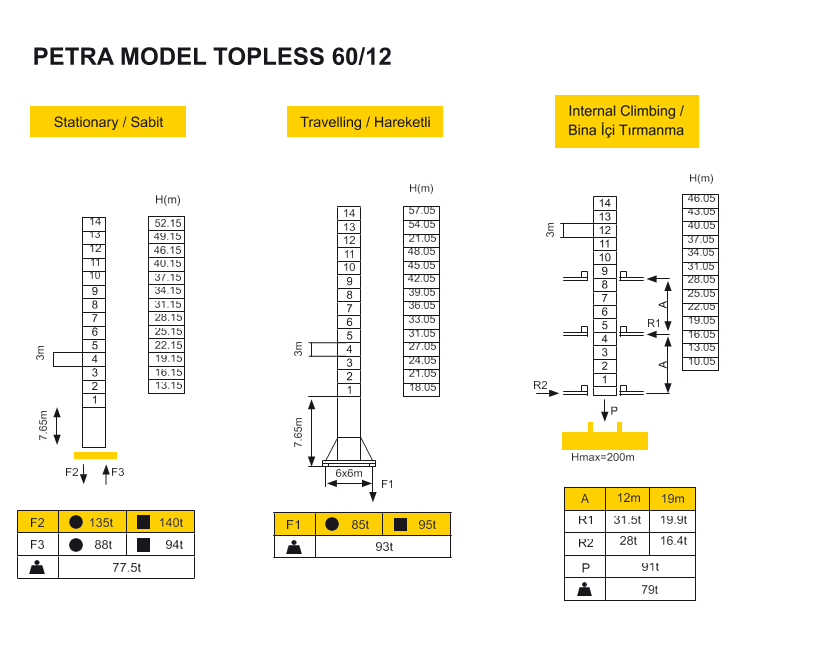

KULE VİNÇ TOPLESS 60-12

İncele »

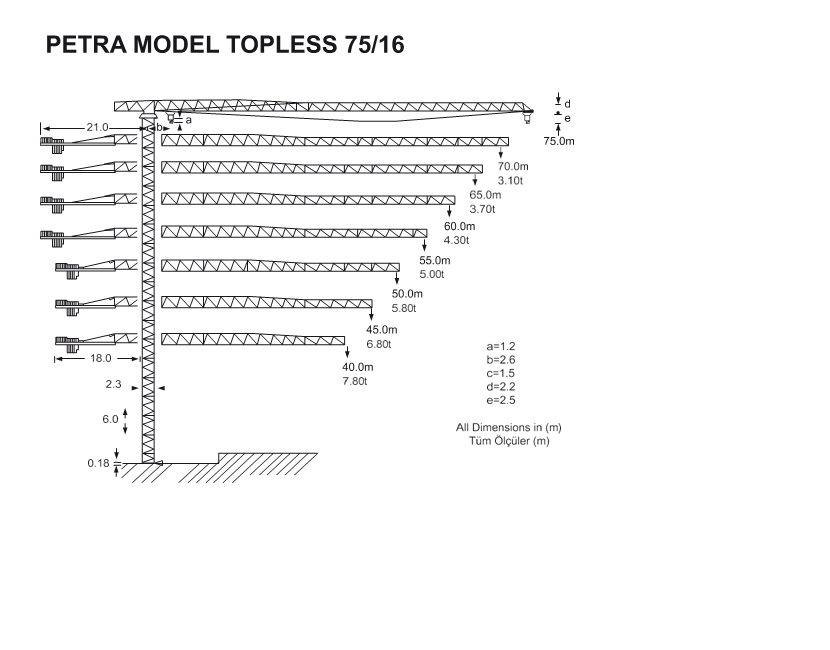

KULE VİNÇ TOPLESS 75-16

İncele »

Kule Vinç KİRALIK

İncele »

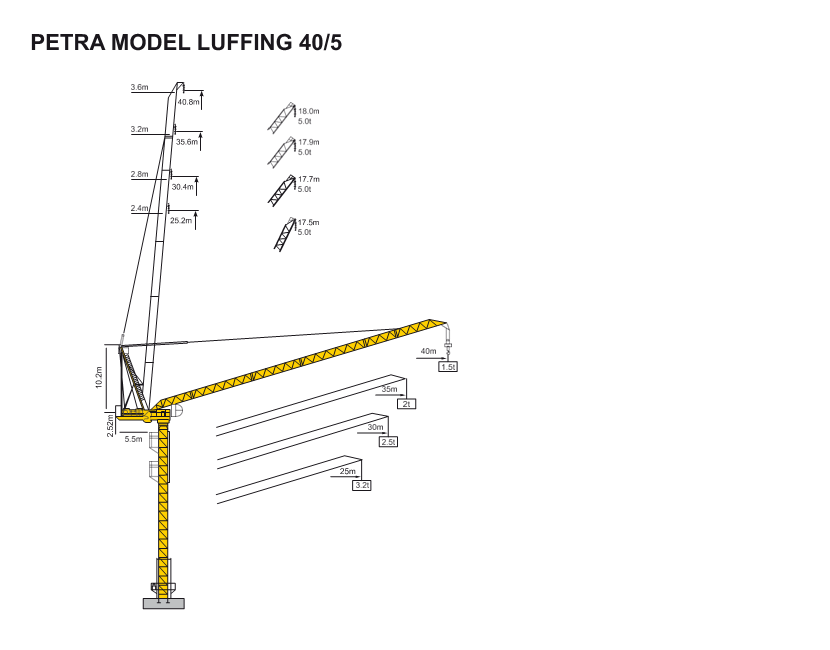

KULE VİNÇ LUFFING 40-5

İncele »

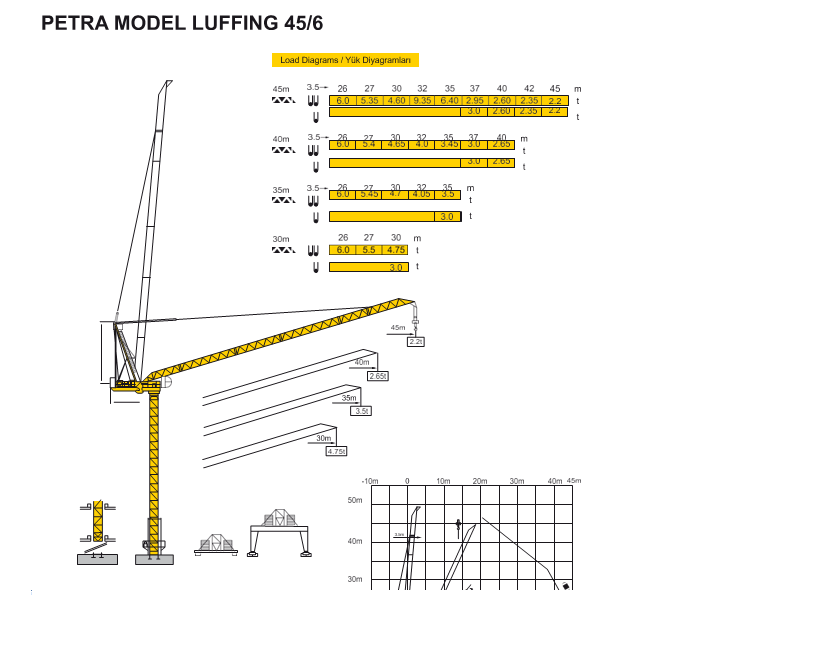

KULE VİNÇ LUFFING 45-6

İncele »

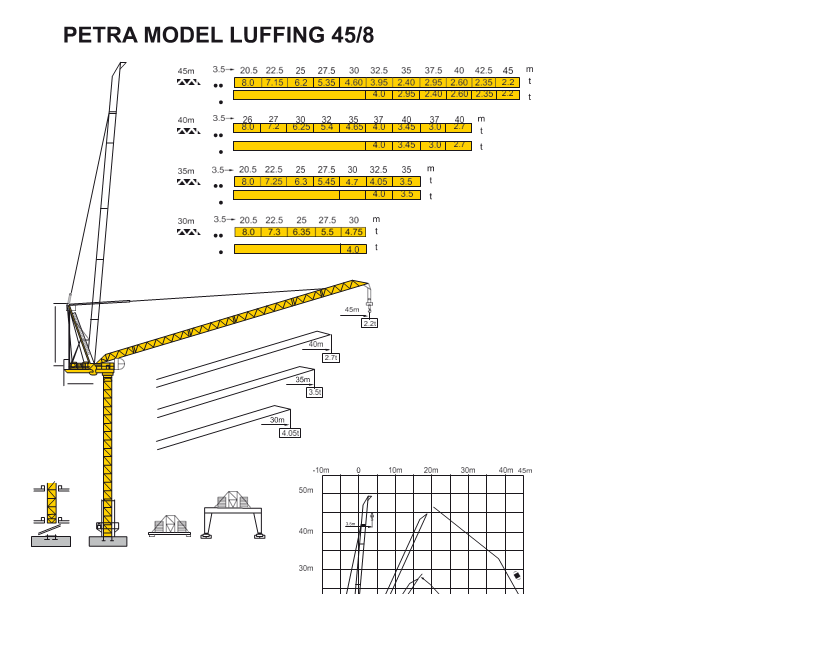

KULE VİNÇ LUFFING 45-8

İncele »

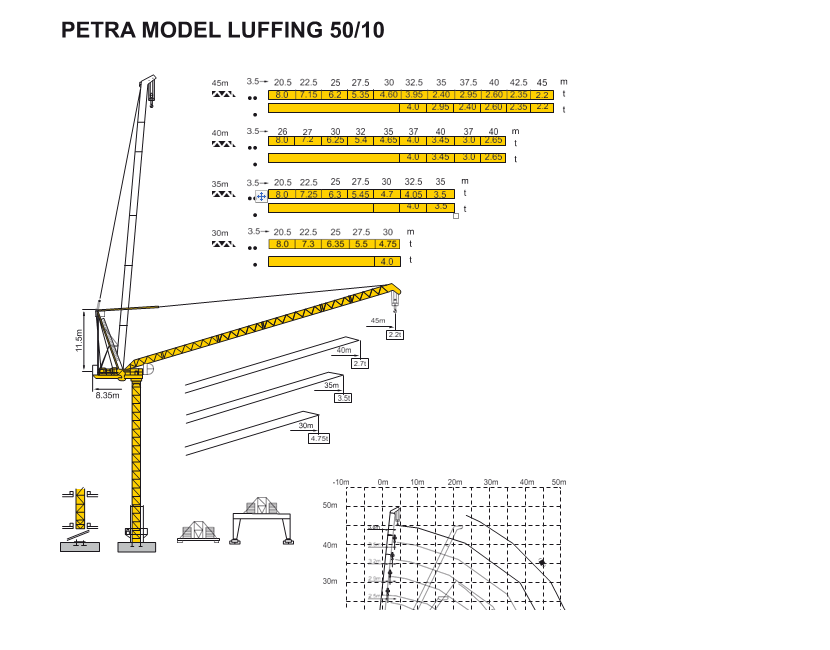

KULE VİNÇ LUFFING 50-10

İncele »

YEDEK PARÇALAR

İncele »

Sektörün vazgeçilmezi olan satış sonrası hizmetlerde, müşteri odaklı yaklaşımımızı bir kez daha ortaya koyarak en iyi servis ve yedek parça hizmetini sağlıyoruz.

Don İncele »

YEDEK PARÇA

İncele »BLOGLAST ARTICLES FROM

The tower crane is among the important construction machinery used in the construction industry.

It enables the necessar...

>> All Blogs

FREQUENTLY ASKED QUESTIONS

WE HAVE COLLECTED ALL THE QUESTIONS AND ANSWERS YOU HAVE IN YOUR MIND.

The tower crane is among the important construction machinery used in the construction industry.

It enables the necessary loads to be carried in the vertical and horizontal axis in the production of buildings in fixed or mobile form at construction sites.

The tower crane is among the important construction equipment used in the construction industry. It enables the necessary loads to be carried in the vertical and horizontal axis in the production of buildings in fixed or mobile form at construction sites. The tower-like form of the hull and the bridge-like platform extending over it play an active role in the construction of high skyscrapers and bridges. While scaffolding-style platforms for lower buildings help to raise the necessary materials to the highest point, the use of tower cranes in high-rise and different forms of skyscraper-style constructions is both practical and time-saving, helping to complete the structures on the targeted date. The weight-bearing part of the machine is called the BOM. In this section, the balance stones that allow it to stay in balance are very important. The fact that it can be adjusted according to the height of the building makes it easily adaptable to any height, while different types of tower cranes are successful in offering solutions suitable for the nature of the work. Since it has a demountable structure, its height can be adjusted by assembling the parts together. Crane operator certification is mandatory for tower crane use. However, since the machine used with a G-class license is not on the road, the license is not mandatory. The operators' place on the crane is the small cabin located between the hull and the BOM. Occupational safety rules are important in order not to cause any accidents during the use of tower cranes, as in every construction machine. It is important that the issues such as that the maintenance is completed before use, that unauthorized use is not allowed, that the load is not carried beyond its capacity, should be done through the control steps to be made before use.

How to use tower crane? The question is directly related to safe use. The machine, which is used by qualified persons, works via electric motor and hydraulic system. The working principle is the logic of decreasing the load on the crane with the change of the center of gravity. While it is important to carry loads that do not exceed the maximum weight capacity, the energy given by the electric motor hydraulic system activates the lever and pulley system. Tower crane working system is based on electric motor and hydraulic system. The system consists of 3 parts. There is a long horizontal arm for carrying loads, another arm behind the arm has a slightly shorter arm with crane engines, electronics and concrete weights to provide balance. The last part is the operator's cabin, where the crane is controlled.

Tower Crane Functions

Due to its tower crane features, it ensures efficient load transfer at high places, while its height can be easily changed depending on the height of the working area. It provides convenience especially for those working in the assembly of large and sensitive parts. Its long arm allows it to work in a very wide area. While the tower crane rises over the interlocking rail systems for the works to be done above, if a fixed base is preferred, the base of the crane rests on a block of concrete approximately 10×10 meters and weighing 180 tons. The tower crane is designed in such a way that it can be used for many buildings in the same area. Thanks to its multi-functional feature, it performs the task of more than one machine or the skeletons used in smaller buildings by itself. The reason why it is called a tower crane

How many tons does the tower crane lift?

As for the question; Although the lifting capacity of the machine varies according to the location of the load in the BOM, the carrying capacity of an average crane is approximately 1250 kg at the far end, while the carrying capacity of the crane at the bottom of the crane is up to 6000 kg. As the load moves away from the body, the carrying capacity of the crane decreases. When it is necessary to carry heavy parts, it is mostly carried in the area close to the body. The remaining transport is done by means of additional mechanisms. When crane operators manage loads from the area where the body and BOM intersect, it is necessary to stop working when the wind speed reaches 50 km/h, as strong winds can cause the crane to overturn. Tower crane is a machine that shortens the work process when used considering the principles of regulation. Although the dimensions of a Tower crane with standard features are 66 meters in height, 80 meters in BOM and 20 tons in maximum lift, these values differ according to the structure of the crane and the proximity of the load to the BOM. Tower cranes are considered among the construction machines that make a significant contribution to the construction industry. When working at height, it rises vertically and allows vertical material transfer. Tower crane lengths vary according to the expectations of the construction site. While standard connections are sufficient in some areas, the use of an attached crane is preferred in some areas. While the types of tower cranes vary according to the ground structure on which they are installed, whether they are movable or immobile is a matter to be decided according to the usage area.

Tower Crane Types and Installation

When the tower crane is assembled by considering the relevant regulations and occupational safety rules, the risk of work accident is minimized. Since the tower crane is large enough to cover the entire construction site and requires working at height, it is among the machines with the highest danger among construction machines. It is very important to manage the occupational safety risk, which is caused by different reasons such as the machine overturning, falling down of the transported load, and falling of the operator. If it is not managed correctly, it results in loss of time and economic losses as well as work accidents. Therefore, not skipping any safety steps during the tower crane installation is the first and most important step to prevent an accident. Crane parts brought to the site for installation are connected to the reinforced concrete floor prepared in accordance with the determined standards, to the rail system or to the truck with mechanical connections. The characteristics and torque values of each connecting piece are specified in the installation instruction. After the concrete base weight is formed, parts of different lengths are placed on top of each other by making bolt and nut connections using a mobile crane, and the tower crane design continues.

After the crane reaches the desired level, it is important to provide a connection with the building from a certain point, taking into account its oscillation. Afterwards, after the cabin and the top of the tower are placed on the body, the balance weights and related parts are fixed to the main body. Thus, the assembly of the platform, also called the tail, is completed so that it can be safely carried by the body. By placing the BOM part, the necessary balance is achieved. The loads are carried by the rope that moves through the hook mounted on the BOM and the drum located in the tail part. While the anemometer placed at the top gives information about the wind speed, the red light placed on the top has the function of warning the aircraft. With the completion of the installation process, the tower crane becomes ready for use through the indicators and controls located in the control cabin. It can be installed on mobile units, as well as on a fixed base or fixed to a rail. If the tower parts fixed to the ground will not be used later, a concrete floor is preferred. If a movable floor is required for the work to be done, the base part is mounted on the rail system and moved over this system. In crane types, which are preferred to be mobile, cranes are mounted on large vehicles such as trucks. Tower cranes differ according to the tower structure with features such as single, interior and exterior, telescopic towers, as well as the base structure. Another type of crane is separated according to the characteristics of the arms. Fixed, luffing and articulated crane arms are designed to provide convenience in the works. Regardless of the type or mode of operation, the establishment of tower cranes for their intended use, not overloading their capacity, operating in suitable weather conditions and having the operator's license to use tower cranes can be counted among the priority occupational safety rules. In addition to the competence of the personnel who will take part in the installation and dismantling work, establishing a lifeline and carrying out these works are among the measures that can prevent life-threatening danger.

Brands

-

Tower Crane | Rental & Sales & Technical Service